Now we have time to prepare the sailings among the Canary Islands during winter and spring. As usual, there are things that need to be looked over or replaced. Among other things, the aft stay tensioner is leaking hydraulic oil and a strand in the wire of one of the top shrouds.

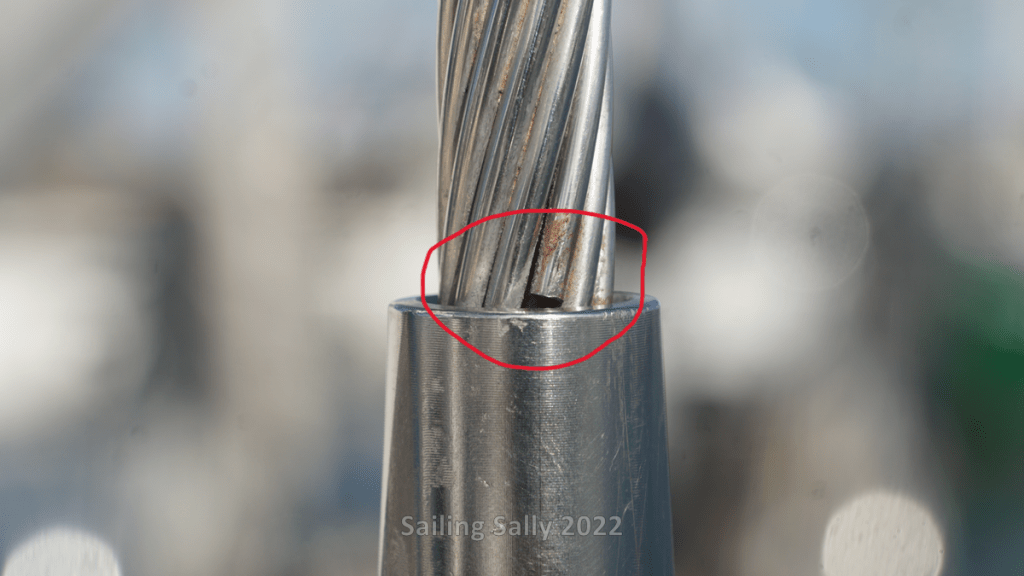

A broken strand at the gauntlet screw of the SB top shroud

After every sailing where salt water is splashed on the deck and superstructure, we wash away the salt deposits with fresh water. When I did this after arriving in Las Palmas, I discovered that a strand was broken in the SB top shroud. The breach has taken place inside the attachment to the lower rigging screw. I’m guessing that it went off already during the sailing between Lagos and Porto Santo when we had strong winds that puts load on that side of the rig.

It was only a matter of time before more strands will start to go off. For each strand, the others have to take an increasingly larger load and in the end they all fail and there is a great risk of losing the mast.

We have had the rig for 4 years and sailed about 12,000 nautical miles when this happened. I contacted Seldén in Sweden, who told me that both top shrouds must be replaced. They suspected that the strand had come off because the end fitting has damaged the strand when the shroud was manufactured.

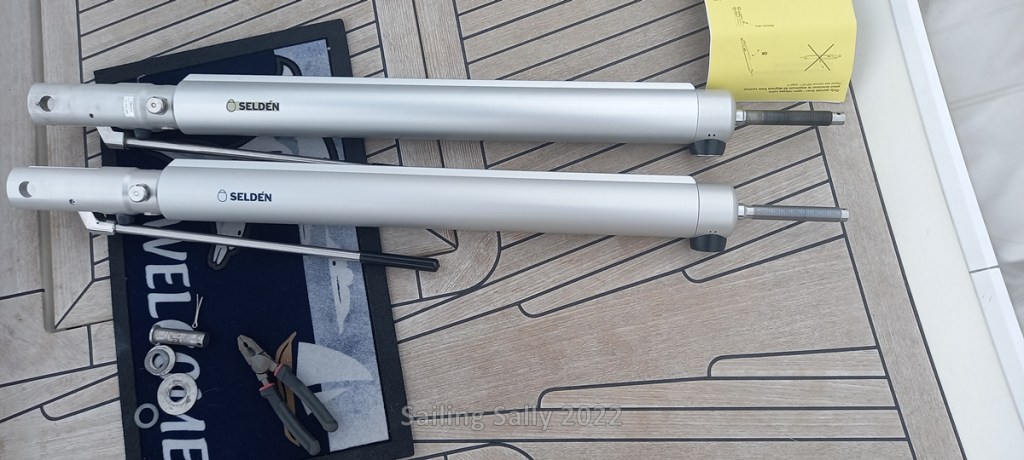

The top shroud is split at each spreader and only the lower part (it is called V1 in rigging terms) on both sides needed to be replaced. I guess you need to change both sides at the same time to guarantee the same length on them.

Seldén guarantees that the rig will last for 3 years or 20,000 nautical miles. Since our rig was over 3 years old but had only sailed 12,000 nautical miles, they agreed to send us new top shrouds (the lower part) if we pay shipping and customs fees.

It is nice to have suppliers who take their responsibility in situations like this.

Alisio’s rigging service in the port of Las Palmas is a supplier for Seldén and they were able to handle the reception of the new top shrouds and they would also make the swap for me.

It took about 3 weeks before the new top shrouds arrived and a week later Alisio’s changed the shrouds.

The aft stay tensioner is leaking hydraulic oil (again)

The aft stay tensioner has been leaking oil for the entire time we’ve had the boat. The first few years it leaked from the pressure gauge and we were told that it was more or less normal and nothing to worry about. Finally the whole meter was empty and when we got to Lagos in 2021, I requested to get a new tensioner under warranty.

Seldén only agreed to repair it. While the boat was ashore in Lagos during the summer of 2021, we sent the leaking aft stay tensioner to Sweden for repair and in the fall of 2021 we put it back. When sailing to Porto Santo in the fall of 2022, we noticed hydraulic oil leaking around the upper joint of the tensioner. The leak was so small that it was not noticed during shorter sailings, but it was only after a day or so of sailing that so much oil had come out that I was able to see oil coming out from the upper joint of the tensioner.

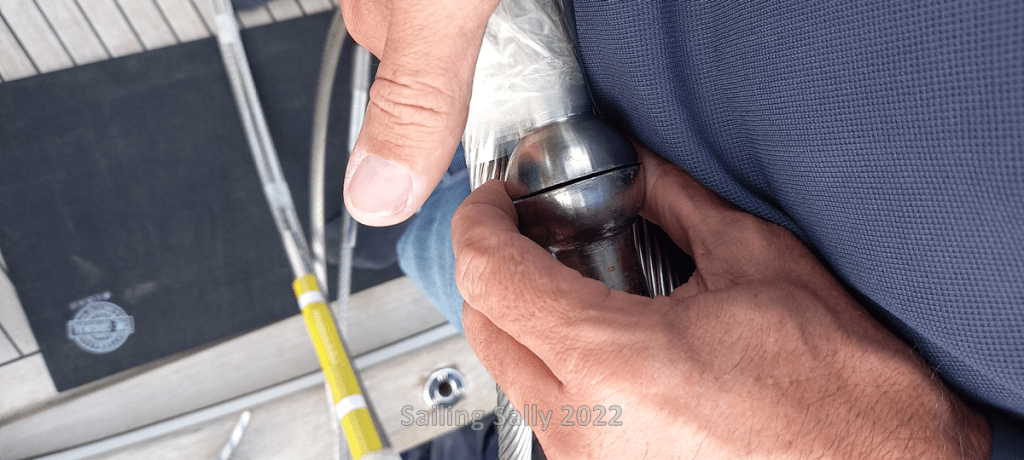

After arriving in Las Palmas, I contacted Seldén about the problem. This time they agree to replace the aft stay tensioner with a new one. To be sure that they will send the correct one, I gave them the model number of the boat (they keep track of the parts they send to Hallberg-Rassy when the boat is built). A few weeks later Alisio’s Sailing got the new aft stay tensioner from Seldén.

Great, but the problem wouldn’t be over quite yet. The new tensioner they sent was of the wrong model and did not fit the boat.

New conversations with Seldén, who apologizes profusely. Fortunately, they have the correct tensioner in stock in Sweden. A week later we have a new package to collect from Alisio’s. This time it’s the right model.

The change is simple and after an hour’s work the new tensioner is in place and the old one left to Alisio’s for return to Seldén. Again, kudos to Seldén for taking responsibility for their products.

Leaking watermaker

When we did the annual major cleaning of the boat before the trip home to celebrate Christmas in Sweden, we discovered that there was a faint trace of rust on the hull under one end of the watermaker’s RO membrane.

Before I can investigate the cause, we must first drain the RO membranes of preservative fluid and disassemble the tubes. One membrane (Filmtec) had expanded a little and was stuck inside the tube. But the membrane from Applied Membranes Inc was still easy to get out of the tube. So now when we have to get new membranes, I choose RO membranes from Applied Membranes Inc.

When changing RO membranes during the pandemic in the Caribbean, we had to use two different types of membranes. The supplier in Antigua only had 1 membrane in our size and when we got to Sint-Maarten we found another supplier, but they used a different make of the RO membranes they sold.

When we disassembled the RO-tubes, it looked like the leak was at the edge of the cover because there was a lot of rust there. But in fact, it was a pipe fitting on the cover that had leaked due to corrosion under the gasket that sits in the fitting.

To successfully fix this leak I need a new u-tube and luckily Echotec can send one on the goodwill account if I cover shipping and duty. To avoid problems with the Spanish customs, they send the damaged part to my home address in Sweden and then we take it with us when we travel back after Christmas and New Year.

New RO membranes will not be as easy to solve, the only supplier that can deliver the membranes I want, is in the USA. I don’t have time to look for a European supplier before we leave Gran Canaria. So ordering RO membranes will have to wait until later. We don’t need the watermaker as long as we are in the Canary Islands.

Rusty faucet in the watertight bulkhead in the bow

The front bulkhead in the bow is waterproof and means that water that leaks in in front of the bulkhead stays there. In order to easily drain out water (condensation) that can collect in the space, there is a tap that you can open and empty to the keel where you can easily pump out with the boat’s bilge pump. So far not a drop has come out of it, but I still want a handle that won’t rust littering the keel hog.

Unfortunately, the handle of the tap is not stainless and has rusted beyond recognition. Last summer I contacted Hallberg-Rassy who sent a new stainless faucet that we took with us to Las Palmas after the trip home last summer and now it’s finally time to change it.

Broken ceiling lights (again)

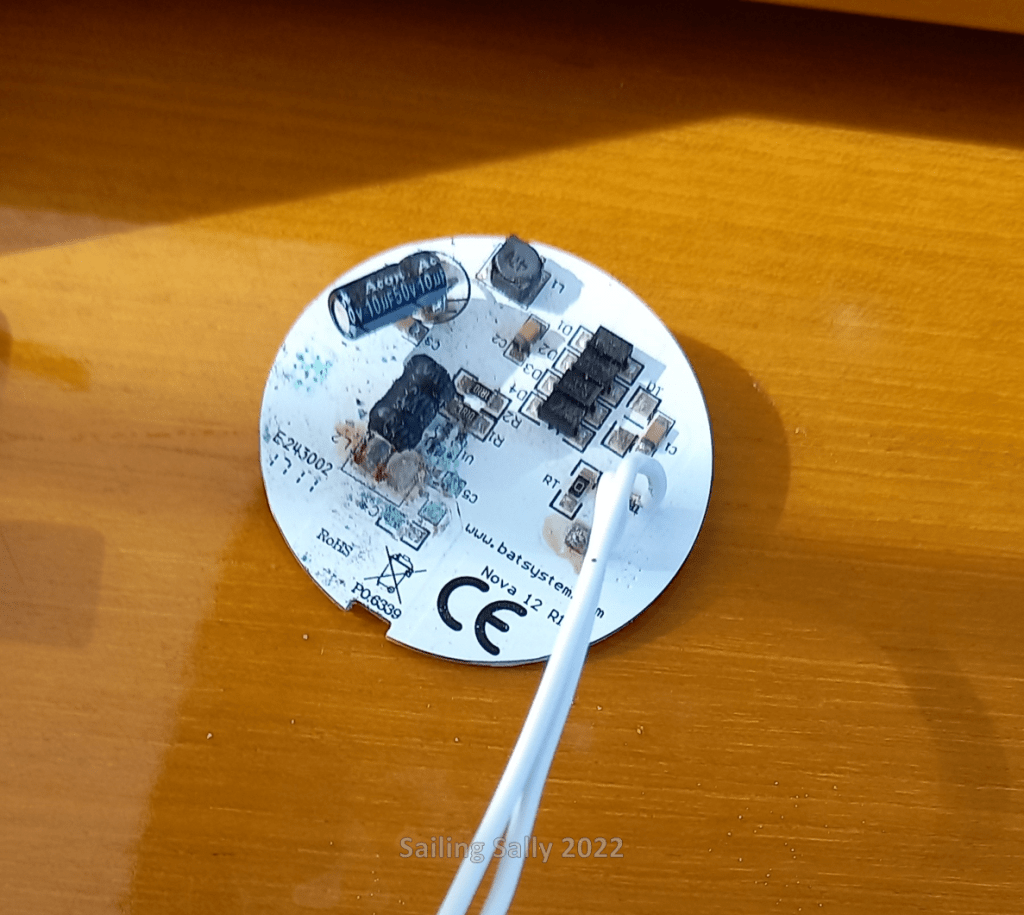

We have LED lights in the ceiling spot lights. Unfortunately they don’t last as long as I would have expected LED lights to. Either they are of poor quality or they are not designed to be connected in series like the HR yard does. The lamps can handle both 12V and 24V and we have a 24V system in the boat. To simplify wiring, the yard has connected two lights in series on a switch. I suspect that the lamp’s built-in DC/DC converter is causing interference that damages the other lamp.

Anyone know how it works?

But this time it wasn’t because of that, but because moisture got on the back of the lamp’s circuit board. I suspect that water has entered through the goose neck pipe for the mast cables and has run down the cables and finally dripped onto the top of this lamp’s circuit board.

Since the lamp had been broken since before the summer, I had ordered a new lamp and brought it to the boat last fall. Once everything is unscrewed and disconnected, it’s a simple job to replace the bulb and reassemble everything.

Engine service

The time has come for a major engine service with the replacement of all filters, impellers, oil, drive belts for the generator and seawater pump. It is also time to change the coolant that has been in use since 2018. Fortunately, Volvo Penta has a well-stocked shop in the Las Palmas harbor where it is easy to get the filters and other things needed for the service. Then it’s just a matter of getting to work, it took us 2 days to do the service 🙂

Drain tap on the fuel pre-filters

In connection with servicing the engine, we decide to fix the problem once and for all by changing the filter in the engine’s fuel pre-filter. As standard, there is a bolt on the underside of the filter holder. The bolt must be unscrewed in order to be able to empty out any water and the diesel that is in the container. It is easy to spill diesel into the bilge when the bolt is unscrewed. In order to avoid having to cover half the engine compartment with oil protection, we will install a tap that is easier to open and control the flow of diesel from with a small hose. It may become a new item on the ”to do” list.

When the tank is empty, we can clean it and put in a new fuel filter.

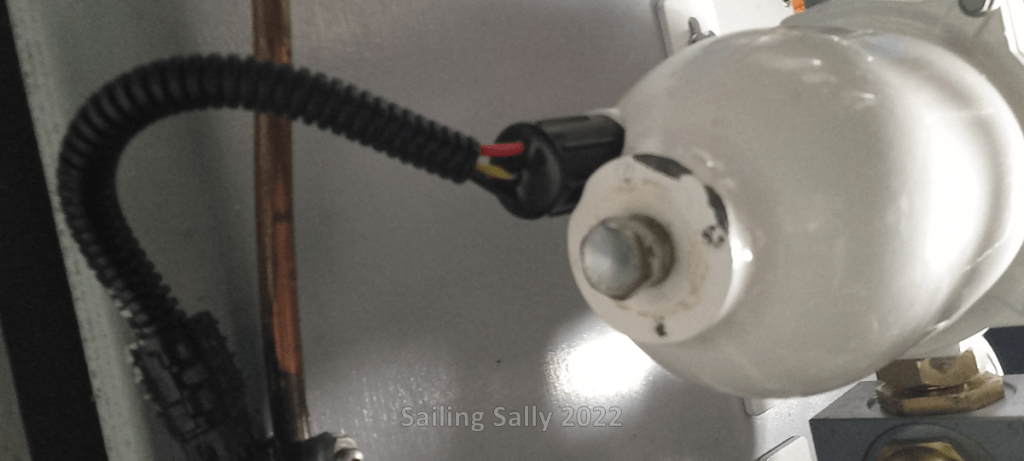

The engine temperature sensor is leaking sea water

For a long time I have seen that some salt water has come out from under the exhaust hose (small rust spots on the engine). In connection with this service, I had devoted myself to finding where it was leaking. Above the leak, there is a sensor on the underside of the exhaust pipe where water appears to have come out. It turns out to be a temperature sensor that measures some sort of engine temperature. I have bought a new sensor for the service work and it is an easy change.

Next blog

Now we are going to take a Christmas break from Sally and travel home to Sweden to celebrate Christmas and New Years. We will return to the boat at the end of January to spend the rest of the winter and spring in the Canary Islands.

Du måste vara inloggad för att kunna skicka en kommentar.